The sector in which Sigam Marmitte operates is the production of exhaust systems to equip cars and industrial vehicles built according to the most recent European standards. More precisely, the production core is the design and manufacture of manifolds for exhaust systems for the automotive and industrial sectors. The mission of the Marfè family started back in 1968 in a small workshop. Today SIGAM is an industry with a strong international vocation, located in a large production area located in Marcianise which involves a production plant and two additional sheds whose acquisition was necessary to better meet the growing needs related to the design and construction of exhaust systems.

At Automechanika Frankfurt, the company will present its new product catalogue, which covers 90% of the Italian and European circulating fleet. The company, founded by brothers Antonio and Gennaro Marfè, has always focused its activity on strong quality standards. Although its main activity is the independent aftermarket, SIGAM has been chosen by well-known original equipment manufacturers for the production of exhausts for OEMs. Today SIGAM focuses on a dual distribution policy. “In Italy – explains Diego Marfè, Export sales manager – we have several warehouses that coordinate the storage and just-in-time distribution of products on a national scale. Abroad, on the contrary, we use a direct channel with leading importers and distributors in the sector, boasting, among other things, significant joint ventures with valid and experienced international operators”.

What will Sigam present to the public at Automechanika Frankfurt in this edition?

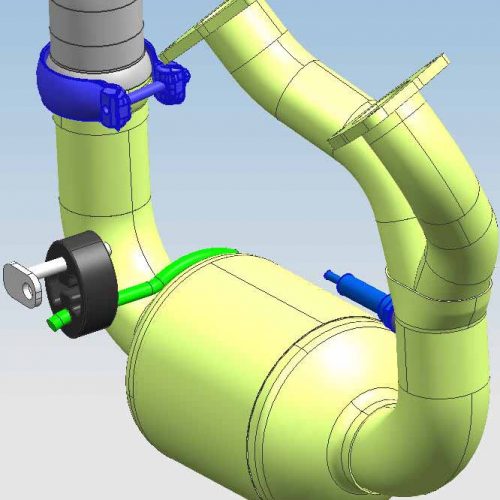

Firstly, the focus will be on the automotive world. We will present examples of exhaust models to give an idea of the quality that underlies and characterises our production. One of our current objectives is, among others, to invest more in the construction of exhaust manifolds and pipes. A process that was born in our factory in Marcianise and that we follow scrupulously, starting from study and design. Large investments have been made to acquire new human resources (specialised engineers) and new working tools, from modern software for the RD sector to the latest generation machinery for the production sector (only in 2016 we bought 4 CNC variable radius tube benders). We manufacture our products starting from the technical data sheet of the application engine, proceeding with the feasibility assessment and the choice of suitable materials. All this in order to pursue the best technical-qualitative results. Then, before putting the product on the market, we make accurate homologation tests, with the collaboration of the DIME of the Faculty of Engineering of Naples and the CNR Istituto Motori. Finally, we test the tightness and effectiveness directly on the cars with special test drives. Our goal is to improve more and more in this type of machining and in its applications both for the four-wheeler world and for the industrial one.

In addition to the products, the new sector catalogue will also be published…

That’s right. Today, the car muffler sector is developing more and more horizontally, in other words, the vastness of the range offered seems fundamental compared to the volumes that characterised the market in the 90s. This implies the continuous development of new references, in line with the current car market. Our new catalogue, which we will bring to the fair in Germany, involves about 3 thousand more references than the previous one and covers 90% of the national and international circulating fleet.

What are the objectives and expectations that the company has had since participating in the German event?

Automechanika Frankfurt is a must for the automotive aftermarket on an international scale. The occasion will be useful for us to meet our family of customers and at the same time see new business opportunities. We have ongoing negotiations with potential customers that we will meet in Frankfurt and we hope to welcome them to our big family soon.